October

2024

PROSUITE NEWS

![]()

Building Quality

In a lot of production environments the quality is checked. Typically this means that by using a paper or digital checklist a quality inspector is going to verify that the product is compliant with the order that was placed by the customer. This is a goodway way to make sure that your production has a high quality standard and thus output. We at ProSuite are convinced that this is not the best way.

We strongly believe that ‘Building Quality’ is the better way. How do we realize this? We start with the original order content from the customer, that we receive from an MES/ERP system. Based on this information we’ll generate, with the configuration made by the process engineer, the work instruction for each single workstation. In this way each work instruction will be almost unique, but reflects exactly what the customer ordered. Via this order info, we set the correct recipe for all devices used for the assembly and only proceed to the next step via the acknowledgment of integrated tools, barcodes, IOT and PLC. In this way we get an objective signal to proceed to the next step and is failure non existing. Thus the need for checking thevquality further down the line is non existing.

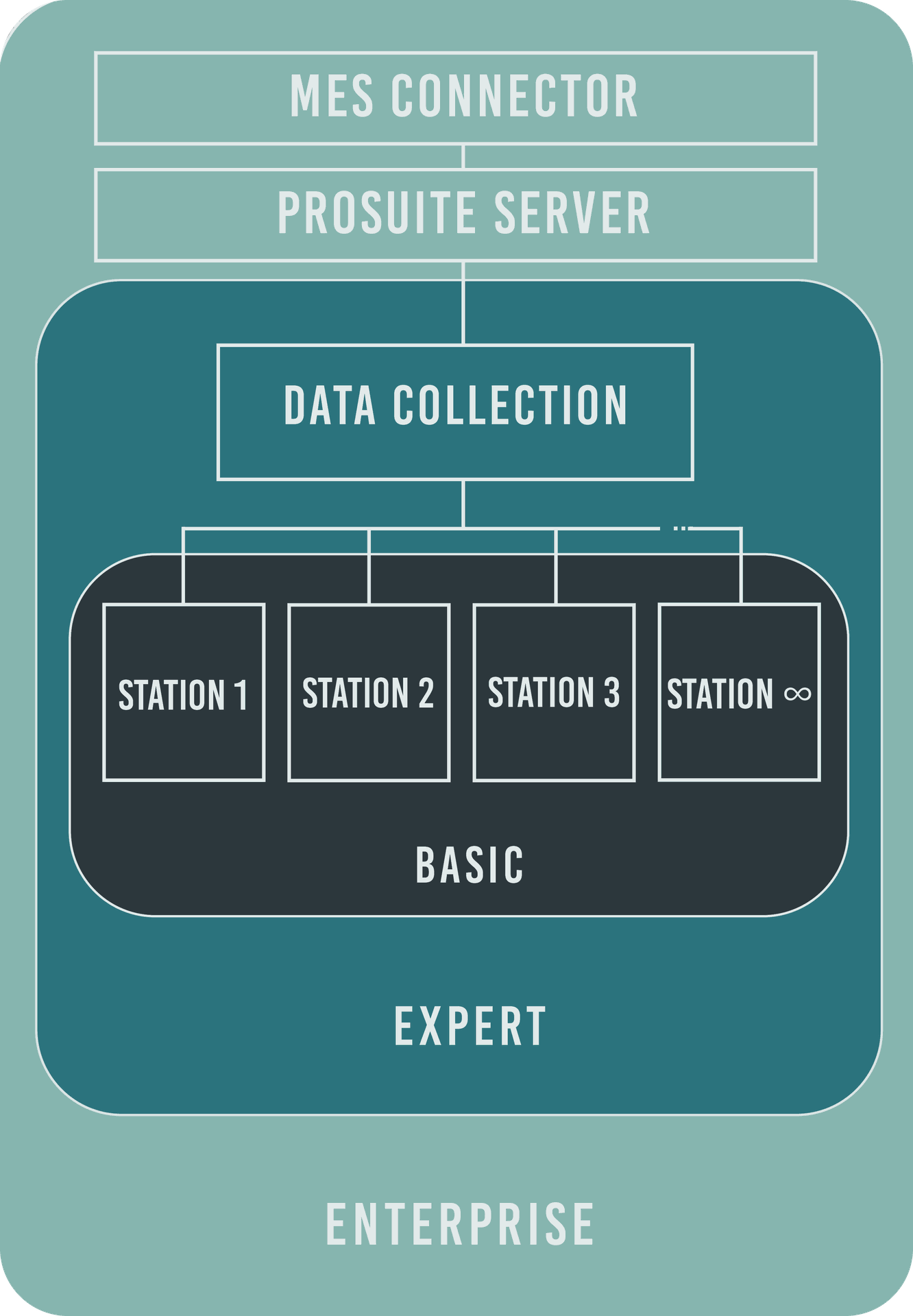

ProSuite floating license

Available from Basic to Enterprise.

Basic from 1 station to...

Expert Basic with datacollection

Enterprise Connect MES/ERP/... for full production control

Register for our webinar to get more insight into ProSuite!

October

2024

PROSUITE NEWS

![]()

Building Quality

In a lot of production environments the quality is checked. Typically this means that by using a paper or digital checklist a quality inspector is going to verify that the product is compliant with the order that was placed by the customer. This is a goodway way to make sure that your production has a high quality standard and thus output. We at ProSuite are convinced that this is not the best way.

We strongly believe that ‘Building Quality’ is the better way. How do we realize this? We start with the original order content from the customer, that we receive from an MES/ERP system. Based on this information we’ll generate, with the configuration made by the process engineer, the work instruction for each single workstation. In this way each work instruction will be almost unique, but reflects exactly what the customer ordered. Via this order info, we set the correct recipe for all devices used for the assembly and only proceed to the next step via the acknowledgment of integrated tools, barcodes, IOT and PLC. In this way we get an objective signal to proceed to the next step and is failure non existing. Thus the need for checking thevquality further down the line is non existing.

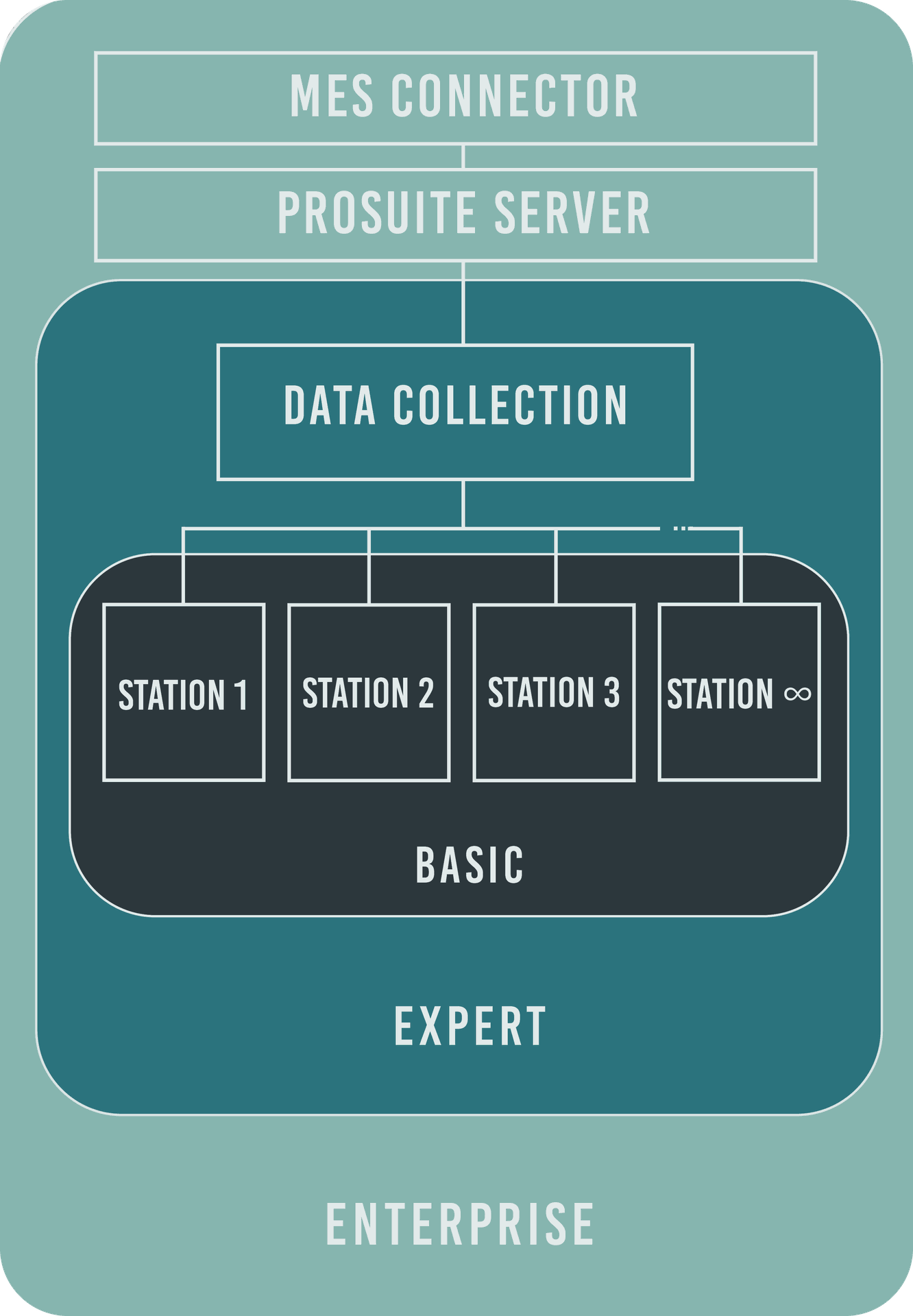

ProSuite floating license

Available from Basic to Enterprise.

Basic from 1 station to...

Expert Basic with datacollection

Enterprise Connect MES/ERP/... for full production control