ProSuite - Manufacturing

Due to complex processes assembly lines still require a lot of human operators, which can lead to human error. To counter this issue, we developed our product ProSuite.

ProSuite combines traceability with process control. Traceability essentially means listing all registered data while process control means ensuring the operator follows the correct guidelines by providing step-by-step instructions through a digital interface and enabling or disabling any tools they need to use.

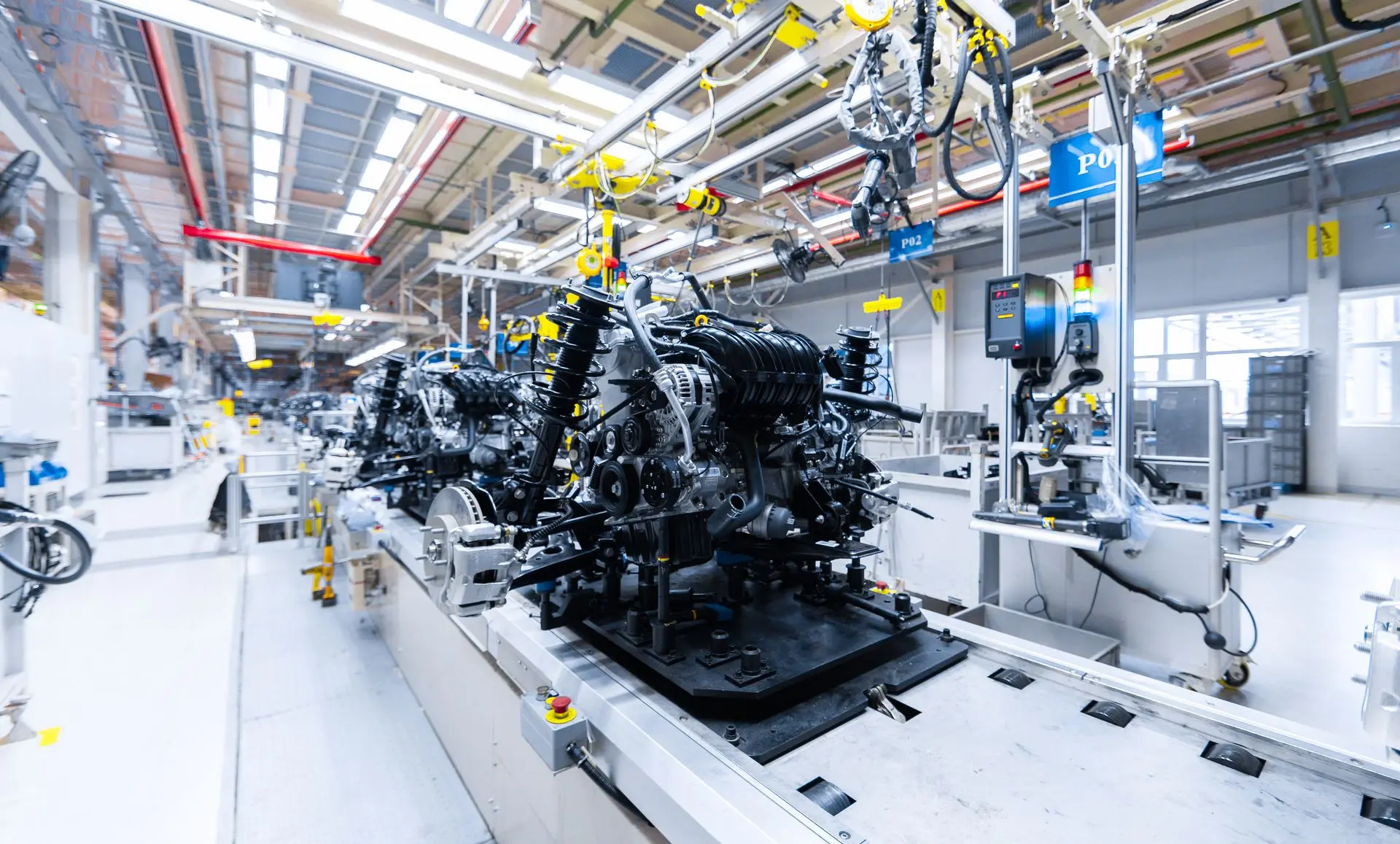

Manufacturing

With ProSuite & IOT you build a correct product.

From basic to full production control configured by the process engineer.

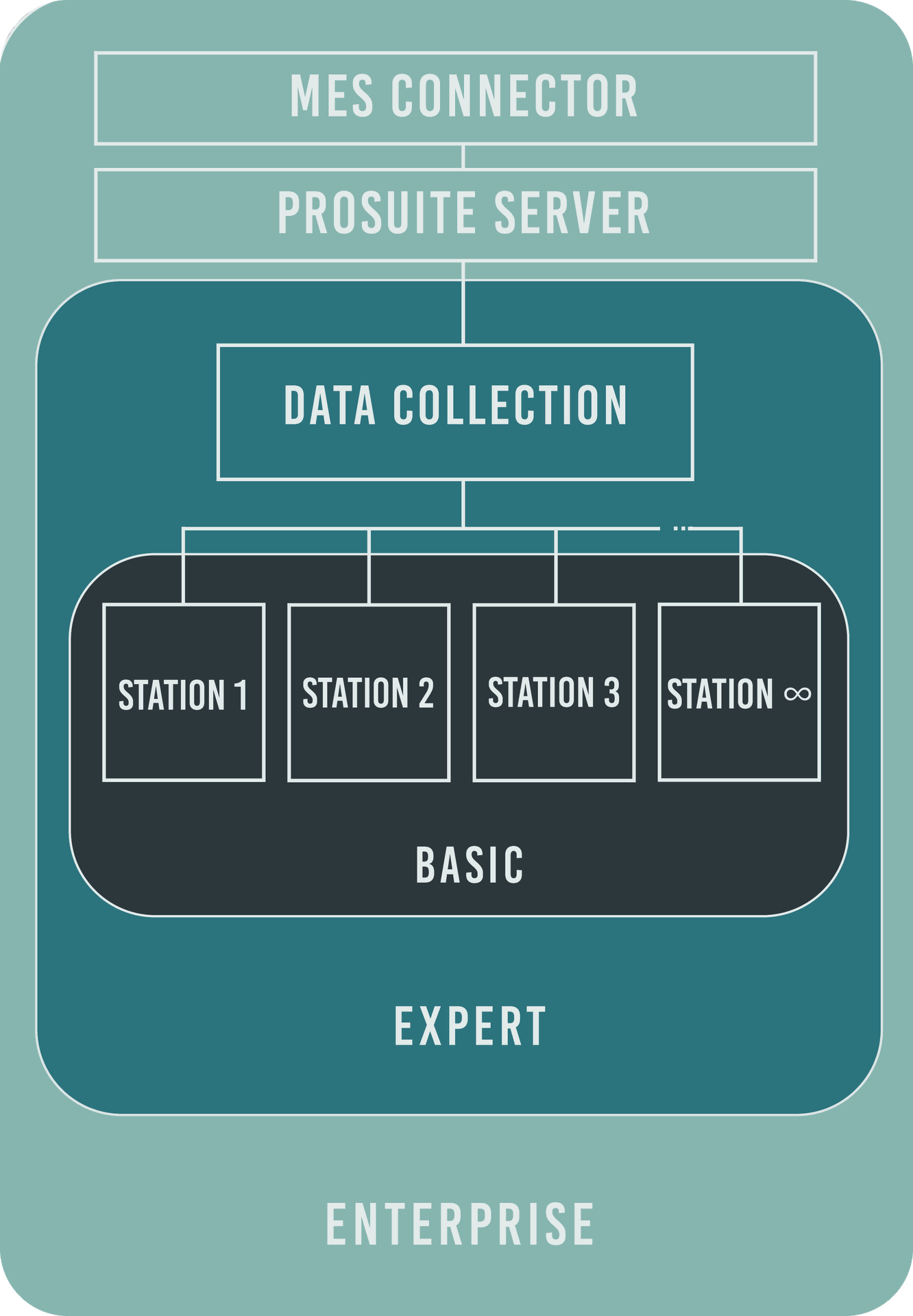

Basic

With ProSuite Basic, we equip one station with our software solutions. Our software solutions guide operators through the required operations at their assembly station. As the operator proceeds through the requested task, the software governs and registers all tightening results of the assembly. All data of the tightening procedures is stored locally. The tool can be disabled if the tightening of the wrong bolt is attempted, or when it happens in the wrong sequence. An interactive socket tray indicates which socket should be used, and disables the tool if the wrong one is in place. The screen guides the operator through the sequence by visually indicating what the operator should do.

Expert

Several single stations can be linked together in order to store all local data on a central server. The server governs the status of all the stations and tracks every part by its serial number. The server notifies when an issue arises, and gives the ability to isolate the products with that serial number. The software integrates together with the customers network, giving it the ability to link the tightening results to all other data of the product with that serial number.

Enterprise

Several stations are linked together to receive the handlings every operator has to execute at their specific station and to store all data on a central server. Once the product is imported into the system using its serial number, all other actions happen autonomously.

Basic

Highly scalable, from 1 station to ...

- Stand alone solution

- Sensors

- Workorders

- Printing label

- Acknowledge

- Small picking

- Positioning

- Process control

- Weight control

- Google glass

- Driven by production barcode

- Camera checking/inspection

- Beamer

- Android compatible

- Custom work

Expert

Basic version with data collection

- Basic +

- Collect data

- Reporting

- Central configuration

- Central storage

- External access to all data

- Dashboard and Reporting server option

Enterprise

Full production control

- Basic +

- Multistations

- Repair function

- Large picking

- Industry 4.0

- Rebalancing

- Full traceability

- Full position

- Line control

- Interface with MES/ERP

- Product/managing variants

- Reporting